With the rapid growth and development of the national economy and society in recent years, the citizens' cultural standards have risen and their lives have been enriched and consequently, the pattern of tap water use in ordinary households has also changed, so the importance of tap water maintenance becomes more important than ever because it requires clean and delicious high quality tap water. It is emerging. However, most citizens have distrust of tap water after the trihalomethane incident in 1990 (2001) due to lead detection and virus detection surges in old water pipes and psychological discomfort caused by vague anxiety, disinfection, odor, and green matter. These lead into a very low drinking rate of tap water. In particular, old pipeshave caused serious damages to citizens, such as the red tap water incident in Incheon in May 2019 and the red tap water incident in Seoul in June of the same year. One of the main reasons for this is the corrosion (and scale) of water pipes.

Biggest issues in water supply piping and industrial factories,

Rust and Scale!!

They cause a variety of secondary damages led by corrosion of pipes and foreign matters caused by peeling of pipe coating, tremendous damages and costs led by large-scale water supply shut-off, and social issues such as sinkholes due to pipe rupture caused by corrosion

Water supply : foreign substances such as green water

Heating and hot water supply : reduced efficiency due to heat transfer

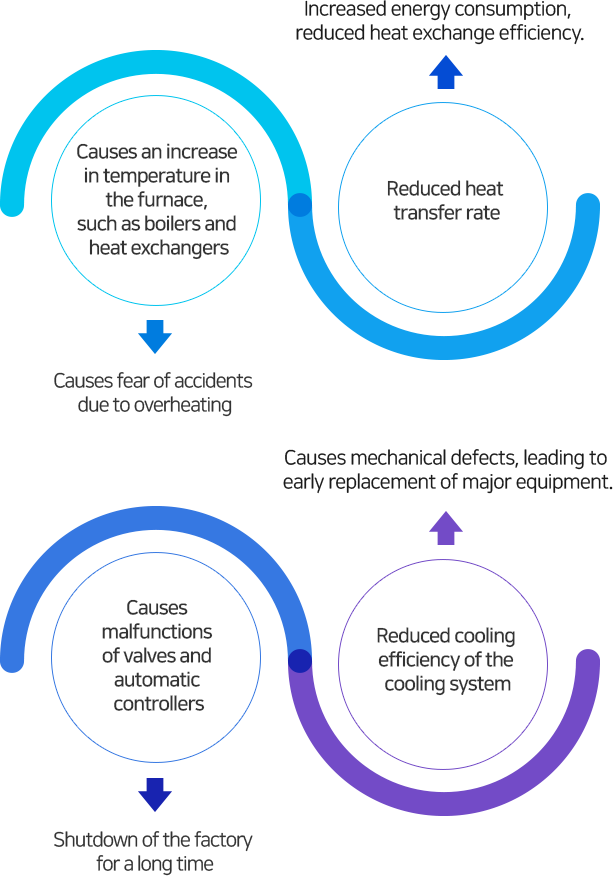

Problems caused by scale inside the pipe

Scale causes enormous invisible damages.

Since the issues of scaleare directly related to the productivity, safety and sales of the factory, it is essential to remove scale of the factory piping and machinery.

wide area water supply, local water supply

use-cooling tower, compressor, boiler, heat exchanger, industrial piping

Swimming pool, hotel, hospital, restaurant, commercial plumbing

water supply line, heating line, hot water supply line, household piping

| Before application | After application |

|---|---|

| Reduced cross-sectional area of piping leads to a decrease in the inherent fluid transport ability of pipes | improved ability |

| Reduced thermal efficiency due to scale inside the heat exchanger | Increased thermal efficiency |

| Reduced cooling efficiency of cabinet system due to secondary infection by scale, bacteria, etc | Prevention of infection / Increased efficiency |

| Creating causes for various malfunctions of valves and automatic control equipment | improvement of such causes |

| Causes mechanical defects | Prevent triggers |

| Early replacement of major equipment | Extended life |

| Factory shutdown for a long time | unnecessary |

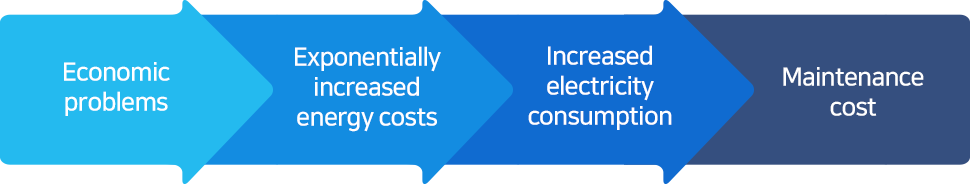

| Increasedmaintenance and production costs | cost reduction |

| Energy costs sharply increased | cost reduction |

| Large facility accident and insufficient safety | Prevention of accident |

| Product Production and Employee Safety, Relationship with Factory Sales | Improvedrelationship |

| Civil complaints caused by green water and foreign substances | Prevention of complaints |